Координатно-измерительные машины HEXAGON mi Leitz SIRIO SX - страница 13

Навигация

Координатно-измерительные машины HEXAGON серии DEA BRAVO C_C HS_HD_HP

Координатно-измерительные машины HEXAGON серии DEA BRAVO C_C HS_HD_HP Госреестр. Методика поверки 64156-16 Координатно-измерительные машины HEXAGON серии TIGO

Госреестр. Методика поверки 64156-16 Координатно-измерительные машины HEXAGON серии TIGO Координатно-измерительные машины HEXAGON серии DEA TORO

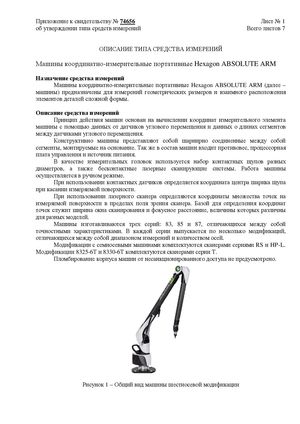

Координатно-измерительные машины HEXAGON серии DEA TORO Машины координатно-измерительные HEXAGON портативные ABSOLUTE ARM

Машины координатно-измерительные HEXAGON портативные ABSOLUTE ARM Координатно-измерительные машины HEXAGON LEITZ PMM-F, PMM-G

Координатно-измерительные машины HEXAGON LEITZ PMM-F, PMM-G Координатно-измерительные машины HEXAGON серии TIGO SF

Координатно-измерительные машины HEXAGON серии TIGO SF

The basic QUINDOS program contains many tools for optimising Powertrain in Aerospace measurement processes and their analysis. Options such as feature-controlled or pallet measurement increase the degree of • Turbine blades automatisation in your measuring process. Communication with • Blisks relational databases, PLC controls, statistical evaluations as well as • Couplings packages for statistical process control make for perfect integration into production. • Housings Specially developed powertrain applications extend the field of application of the Leitz SIRIO SX: Powertrain in Machine Construction QUINDOS has further options for machine construction applica- Powertrain in Automobile Manufacture tions, e.g.: Practically all parts in a vehicle‘s drive train belong to the repertoire QUINDOS Screw Compressor – Inspection of male and female of the Leitz SIRIO SX: rotors, transverse or axial sections, actual-nominal comparisons, evaluation of lead, pitch, root and tip circle etc. with gap calculation • Crankcases, with their critical features of cylinder bores of rotor pairs. • Cylinder heads, with the critical features of valve stem guides and QUINDOS Step Gear – Inspection of the profiles of three-dimensio- seats nal step gears (roller gears) with cylindrical or globoid shaped carri- • Crankshafts, with the critical features of main and piston bearings ers. The surface geometry is calculated from the transmission law. • Camshafts, with the critical features of cams and bearings QUINDOS Polygon – Measurement and evaluation of type P3G po- • Conrods, with the critical features of little and big ends, special lygons according to DIN 32711 and of type P4C polygons according shapes to DIN 32712. • Constant velocity joints (CVJ) CAD-based Offline-Programming and I++ Simulator The Leitz SIRIO SX is used as a measuring machine in production mainly in multishift operations. With offline programming QUINDOS offers the best prerequisites for avoiding downtime. Offline programming allows you to simply modify existing measuring programs. CAD models can be used to generate precisely positioned measuring points. In combination with the I++ Simulator you can run through all the measurement processes and analyses remote from the actual machine. 13