Координатно-измерительные машины MITUTOYO серии Surface Measure PRE1376 - страница 7

Навигация

Координатно-измерительные машины MITUTOYO серии MACH-3A 653 PRE1339

Координатно-измерительные машины MITUTOYO серии MACH-3A 653 PRE1339 Координатно-измерительные машины MITUTOYO Каталог

Координатно-измерительные машины MITUTOYO Каталог Координатно-измерительные машины MITUTOYO PRE1172

Координатно-измерительные машины MITUTOYO PRE1172 Координатно-измерительные машины MITUTOYO с ЧПУ больших размеров (CNC-CMM)-PRE1341

Координатно-измерительные машины MITUTOYO с ЧПУ больших размеров (CNC-CMM)-PRE1341 Измерительные головки для Координатно-измерительных машин MITUTOYO

Измерительные головки для Координатно-измерительных машин MITUTOYO Госреестр. Методика поверки 64249-16 MITUTOYO Машины координатные измерительные портальные LEGEX серии 356

Госреестр. Методика поверки 64249-16 MITUTOYO Машины координатные измерительные портальные LEGEX серии 356

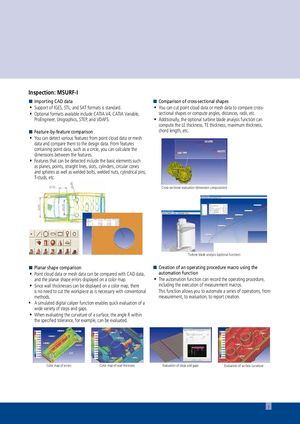

Inspection: MSURF-I ■ Importing CAD data ■ Comparison of cross-sectional shapes • Support of IGES, STL, and SAT formats is standard. • You can cut point cloud data or mesh data to compare cross- • Optional formats available include CATIA V4, CATIA Variable, sectional shapes or compute angles, distances, radii, etc. ProEngineer, Unigraphics, STEP, and VDAFS. • Additionally, the optional turbine blade analysis function can compute the LE thickness, TE thickness, maximum thickness, ■ Feature-by-feature comparison chord length, etc. • You can detect various features from point cloud data or mesh data and compare them to the design data. From features containing point data, such as a circle, you can calculate the dimensions between the features. • Features that can be detected include the basic elements such as planes, points, straight lines, slots, cylinders, circular cones and spheres as well as welded bolts, welded nuts, cylindrical pins, T-studs, etc. Cross-sectional evaluation (dimension computation) Turbine blade analysis (optional function) ■ Planar shape comparison ■ Creation of an operating procedure macro using the • Point cloud data or mesh data can be compared with CAD data, automation function and the planar shape errors displayed on a color map. • The automation function can record the operating procedure, • Since wall thicknesses can be displayed on a color map, there including the execution of measurement macros. is no need to cut the workpiece as is necessary with conventional This function allows you to automate a series of operations, from methods. measurement, to evaluation, to report creation. • A simulated digital caliper function enables quick evaluation of a wide variety of steps and gaps. • When evaluating the curvature of a surface, the angle R within the specified tolerance, for example, can be evaluated. Color map of errors Color map of wall thickness Evaluation of steps and gaps Evaluation of surface curvature 7