Координатно-измерительные машины WENZEL PRODUCT RANGE - страница 104

Навигация

Координатно-измерительные машины LH 87 Wenzel

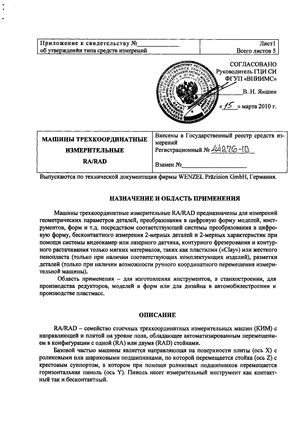

Координатно-измерительные машины LH 87 Wenzel Госреестр. Описание типа 44276-10 Wenzel Машины трехкоординатные измерительные RA, RAD

Госреестр. Описание типа 44276-10 Wenzel Машины трехкоординатные измерительные RA, RAD Координатно-измерительные машины Wenzel LH 2015

Координатно-измерительные машины Wenzel LH 2015 Координатно-измерительные машины Wenzel серии LH 108

Координатно-измерительные машины Wenzel серии LH 108 Координатно-измерительное оборудование Wenzel серии LH 54

Координатно-измерительное оборудование Wenzel серии LH 54 Координатно-измерительные машины Wenzel серии LH 1010

Координатно-измерительные машины Wenzel серии LH 1010

Applications COMPUTED TOMOGRAPHY PRODUCT RANGE FIELDS OF APPLICATION exaCT IS THE SOLUTION FOR MANY TASKS Computed tomography makes it possible to perform mea- The exaCT S has a measuring volume up to 48 mm in surements on a very broad range of parts from plastic height, 83 mm in diameter and voltage of up to 130 kV. parts to fibre composite components up to and including The exaCT M has a measuring volume of 250 mm in light metal parts. The density of the material as well as height, 150 mm in diameter and voltage of 225 kV. the geometry and wall thicknesses of the objects ulti- kV. The exaCT L has a measurement volume of 300 mm in mately determine if they can be measured this way. height, 235 mm in diameter and a voltage of up to 225 kV. The exaCT U has a measurement volume of 700 mm in height, 330 mm in diameter and a voltage of up to 300 APPLICATION AREAS MEASURING TECHNOLOGY TESTING TECHNOLOGY Dimensional checks Material defect analyses Measurement of standard geometries and freeform Non-destructive testing for e.g. blowholes, pores or surfaces including shape and position tolerances cracks Wall thickness analysis Structural analysis Color representation of component wall thickness Visualization of material and component structures distribution Nominal-actual comparisons Assembly checks Representation of deviation from CAD model or Control of assembly results, functional and error master component analyses Tool and component optimization Joining technology tests Compensation of shrinkage and warpage Checking errors in welded, soldered, glued or riveted joints Development, Rapid Prototyping and Re- Electronics testing verse Engineering Inspection of soldered and glued joints Creation of CAD models from the scan data 1804