Координатно-измерительные машины WENZEL PRODUCT RANGE - страница 132

Навигация

Координатно-измерительные машины LH 87 Wenzel

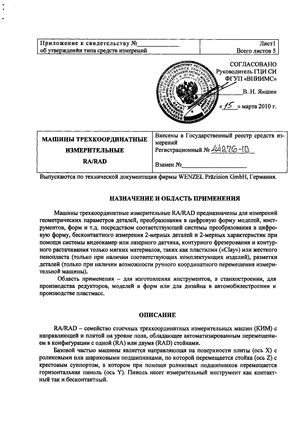

Координатно-измерительные машины LH 87 Wenzel Госреестр. Описание типа 44276-10 Wenzel Машины трехкоординатные измерительные RA, RAD

Госреестр. Описание типа 44276-10 Wenzel Машины трехкоординатные измерительные RA, RAD Координатно-измерительные машины Wenzel LH 2015

Координатно-измерительные машины Wenzel LH 2015 Координатно-измерительные машины Wenzel серии LH 108

Координатно-измерительные машины Wenzel серии LH 108 Координатно-измерительное оборудование Wenzel серии LH 54

Координатно-измерительное оборудование Wenzel серии LH 54 Координатно-измерительные машины Wenzel серии LH 1010

Координатно-измерительные машины Wenzel серии LH 1010

WM | Quartis PRODUCT RANGE SOFTWARE WM | Quartis supports manual and CNC measuring machines with tactile (touching) and optical (non-con- tact) sensors and is therefore predestined for automated multi-sensor applications. Scanning with high point density allows the acquisition and evaluation of surface shape tolerances as well as the color-coded representa- tion of component deviations. Profiles can be captured and evaluated with one image Detection of surface shape with optical sensor and color-coded display Non-contact measurement with optical sensors of component deviations Renishaw REVO and PH20 5-axis probes increase measurement throughput with very high scanning speeds and point rates. Stepless rotation and swivel angles allow time-saving, through optimum align- ment of the probe to the component. Measurement with the rotary axes leads to high system accuracy due to minimal traverse paths of the mea- suring device. In addition, the REVO system allows the measurement of roughness. 5-axis probes such as PH20 significantly increase measurement throughput 11302