Координатно-измерительные машины WENZEL PRODUCT RANGE - страница 135

Навигация

Координатно-измерительные машины LH 87 Wenzel

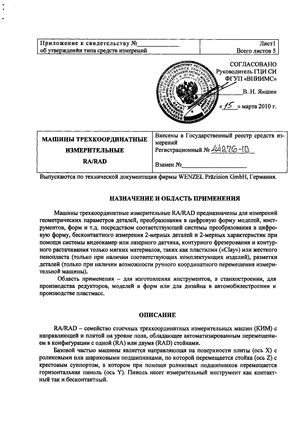

Координатно-измерительные машины LH 87 Wenzel Госреестр. Описание типа 44276-10 Wenzel Машины трехкоординатные измерительные RA, RAD

Госреестр. Описание типа 44276-10 Wenzel Машины трехкоординатные измерительные RA, RAD Координатно-измерительные машины Wenzel LH 2015

Координатно-измерительные машины Wenzel LH 2015 Координатно-измерительные машины Wenzel серии LH 108

Координатно-измерительные машины Wenzel серии LH 108 Координатно-измерительное оборудование Wenzel серии LH 54

Координатно-измерительное оборудование Wenzel серии LH 54 Координатно-измерительные машины Wenzel серии LH 1010

Координатно-измерительные машины Wenzel серии LH 1010

PRODUCT RANGE SOFTWARE WM | Quartis Special applications Get the most out of your measurement software P Measure and evaluate roughness with Renishaw REVO P Use of third-party measurement software via WM | I++ DME Server based on WM | Quartis P Virtual measurement on actual data from Computertomographs and optical scanners using WM | CTAnalyzer and WM | PointMaster P Multi-column systems can be operated simultaneously and collision-free with up to 8 CNC measuring devices. This dramatically reduces the measuring cycle time Measure roughness with Renishaw REVO SFP2 roughness sensor P Measurement of turbine blades in WM | Quartis and evaluation in WM | BladeAnalyzer on WENZEL CORE mul- tisensor measuring devices P Export of tool correction data, e.g. for eroding machines P Automation and integration of the measuring system in the production process P Use as a test device with the Renishaw Equator Multi-device operation with up to 8 measuring devices Program start and data transfer from bar and data matrix codes YOUR ADVANTAGES P Low operating costs AT A GLANCE Low training costs | Investment protection thanks toongoing further development and regular updates | Software maintenance contract at a reasonable price | P Powerful, universal measurement software Volume discounts Measurement of standard geometry, freeform and P Connectivity curves | For manual and CNC measuring devices | Imports from all common CAD systems | Data transfer With tactile and optical sensor technology | For single point and scanning acquisition | Standard-compliant to external statistical software | Connection of various evaluation | Impressive measurement reports measuring machines | Automation solutions P Simple operation P Swiss Made Quality User-friendly Microsoft Fluent Interface | Dynamic Reliable | Precise | Innovative | Ribbons | Structured Workspace Down-to-earth | Windows 10 compatible 11335