Координатно-измерительные машины WENZEL PRODUCT RANGE - страница 82

Навигация

Координатно-измерительные машины LH 87 Wenzel

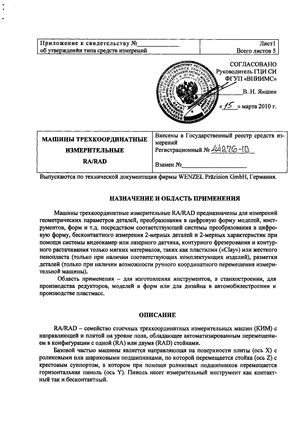

Координатно-измерительные машины LH 87 Wenzel Госреестр. Описание типа 44276-10 Wenzel Машины трехкоординатные измерительные RA, RAD

Госреестр. Описание типа 44276-10 Wenzel Машины трехкоординатные измерительные RA, RAD Координатно-измерительные машины Wenzel LH 2015

Координатно-измерительные машины Wenzel LH 2015 Координатно-измерительные машины Wenzel серии LH 108

Координатно-измерительные машины Wenzel серии LH 108 Координатно-измерительное оборудование Wenzel серии LH 54

Координатно-измерительное оборудование Wenzel серии LH 54 Координатно-измерительные машины Wenzel серии LH 1010

Координатно-измерительные машины Wenzel серии LH 1010

CORE Series PRODUCT RANGE SHOPFLOOR SOLUTIONS OVERVIEW WENZEL CORE OPTICAL HIGH SPEED SCANNING MEASUREMENT OF BLADES, BLISKS AND IMPLANTS Hollywood, for example, used it for the film “The surfaces, whether shot peened, lacquered, polished or Core”. In sports, “core training” means the training matt. Due to the unique optical sensors of the CORE of the central body part, in physics “core” is the most product line it is possible to measure all these surfaces. important part of a nuclear reactor in which the chain Some may now think that optical sensors cannot mea- reaction takes place. No matter what we have looked sure everything. That’s right, every technology has its at so far, they all have one thing in common: it is about limits. For this reason, WENZEL has developed a hybrid the innermost, the central part. sensor that combines the characteristics of optics and tactile sensors and is outstanding in this regard, but not In addition to measurements in the measuring room, it only are the sensors to be emphasized here, also the is now important to move metrology into the produc- machine itself impresses with its small space require- tion area close to the processing machines in order ment in comparison to similar measuring machines. to be able to react quickly to deviations. With this in The CORE product range is also characterized by its mind, WENZEL’s CORE product range was developed incredible flexibility. Depending on the model, the CORE for the central part of a production plant - the quality can be equipped with 6 axes and a measuring turntable. of the products. No matter whether the measurement is This combination allows almost unrestricted access to carried out directly after production or during post-pro- the components in order to measure as many features cessing within the maintenance cycle at a later point in as possible in a single operation without re-clamping. time, the CORE is the appropriate coordinate measuring This measurement is not done in hours, days or weeks, machine for this. The measuring machine can be used no, the development of the CORE product line has been directly in the production area and measure the relevant designed to measure within the cycle time of produc- characteristics. It is possible to measure on almost all tion. Fast measurements can be achieved as a result of 2842