Термоусадочные машины Pokolm серии TSI 3510 - страница 2

Навигация

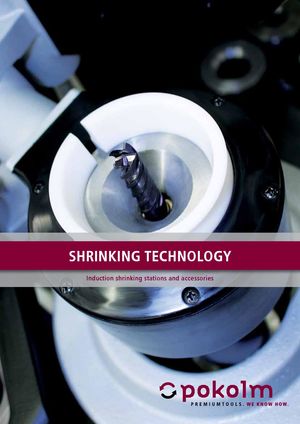

u PRODUCTINFORMATION TSI 3510 u PRODUCTINFORMATION TSI 3510 INDUCTIVE SHRINKING TE C H N O L O G Y TABLE OF CONTENTS FIRST OPERATION: SHRINKING, THEN MILLING INDUCTION SHRINKING UNIT TSI 3510 u fast shrinking operation with maximum safety Page 4 S Shrinking Technology convinces everybody comparedwith conventional chucking methods from the past.For applications with extended requirements, POKOLMhas developed a complete new Adaptor-System: What counts? Absolute concentricity and highest precision. DuoPlug® a combination of screwing and shrinking. This unique and patent protected technology secures This guarantees much longer tool life. Shrinking Technology absolute concentricity and rigidity – also with long reach TECHNICAL DATA secures also a safe load transmission and an extremely adaptors and roughing with High Speed Technology. u operators control and accessories Page 5 high torque- and balance quality. Its capability for extended revolutions is the best assumption for getting Pokolm-Voha offers for Shrinking Technology a highly optimum surface quality in order to save expensive finish qualified range: processes. u a top-class Induction Shrinking Unit u Shrinking arbors for all possible machine connections SUITABLE ARBOR CONNECTIONS Compared with usual Milling Chucks, Shrinking Arbors u our Milling Cutter Bodies DuoPlug® u for shrinking process Page 6 allow distinctly slim adaptors and extend the variety of u our Solid Carbide Adaptors DuoPlug® applications, which would be impossible without this u our “zero-reach” Shrinking Arbors most modern process. (additional information about the POKOLM DuoPlug® System can be found under chapter “Milling Cutter Bodies” of our catalogue.) POKOLM DuoPlug® u the combination clamping system Page 7 TSI 3510 2 3

Термоусадочные машины Pokolm

Термоусадочные машины Pokolm