Координатно-измерительные машины COORD3 серии MCT-PLUS - страница 4

Навигация

Координатно-измерительные машины COORD3 серии UNIVERSAL 07.07-9.08-10.08

Координатно-измерительные машины COORD3 серии UNIVERSAL 07.07-9.08-10.08 Координатно-измерительные машины COORD3 серии KRONOS NT

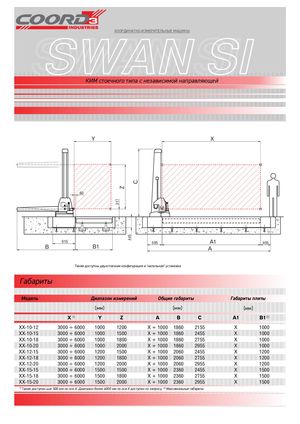

Координатно-измерительные машины COORD3 серии KRONOS NT Координатно-измерительные машины COORD3 серии SWAN-SI

Координатно-измерительные машины COORD3 серии SWAN-SI Координатно-измерительные машины COORD3 серии ARES-NT-XL-13.09.07 MOT

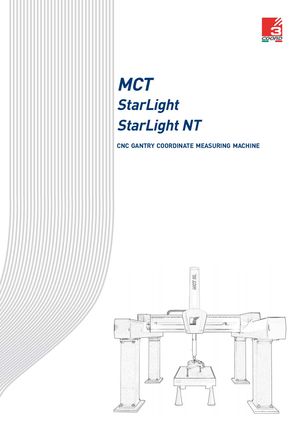

Координатно-измерительные машины COORD3 серии ARES-NT-XL-13.09.07 MOT Координатно-измерительные машины COORD3 серии MCT-STARLIGHT

Координатно-измерительные машины COORD3 серии MCT-STARLIGHT

TECHNICAL CHARACTERISTICS STRUCTURE ENVIRONMENT CNC Coordinate Measuring Machine, Gantry type architecture Temperature Range for Metrological Specification: Guideways: Temperature Range: 18 ÷ 22 °C X Axis: guideways on stabilized welded steel beams Max. gradient per hour:: 1,0 °C/h Y Axis: guideways on stabilized welded steel beam Max. gradient per day: 2,0 °C/24h Z Axis: micromachined anodized light alloy extrusion Max. gradient in space: 1,0 °C/m Drive Method: Operating Temperature: X Axis: rack & pinion system, Dual Drive system on both X beam 15 ÷ 35 °C on MCT Plus (optional for StarLight) Relative Humidity: Y Axis: rack & pinion system 40 ÷ 80 % (non condensing) Z Axis: zero hysteresis friction drive Acceptable Vibrations: Sliding System: (vibration acceleration between peaks) Air bearings on all axes 30 mm/s2 from 1 to 10 Hz Motion Control: 15 mm/s2 from 10 to 20 Hz DC servomotor on all axes 50 mm/s2 from 20 to 100 Hz Thermal Compensation: Multi-sensors temperature compensation system for part and Optional scale (Optional) -Metrology Room or CMM protection system Measuring System: Linear scales, System Resolution: 0,1 μm. Dual Scale/Reader on X axis AIR SUPPLY Air Consumption: MCT StarLight: max. 300 Nl/min PROBING SYSTEM MCT Plus: max. 450 Nl/minMinimum Air Supply: Manual Probe Head: MCT StarLight: 6 Bar MIH, MH20, MH20i MCT Plus: 6,5 Bar Motorized Probe Head: PH10, PH10M, PH10MQ Point-to-point Trigger Probe:TP2, TP20, TP200 POWER SUPPLY Analog Contact Probe: Power Supply Voltage: SP25 (Optional) 230 V ± 10%; 50 Hz ± 2% (single phase) Laser Probe: Maximum Power Consumption: Metris LC/XC series (qualification sphere included) MCT StarLight: 16 A 1600 W Stylus and Probe Changer: MCT Plus: 16 A 2000 W Fully automated stylus and probe changers (data for CC3 controller only) Optional -Voltage: 115 V ±10%; 60 Hz ±2% (single phase) OPTION Multi-wire cable WARRANTY PC & Printer 12 months from the date of acceptance test or a maximum of 15 Training c/o Coord3 Center or Agents months from date of shipment Installation by Coord3 or Agents personnel Coord3 Industries S.r.l. Headquarters/Administration and Sales: Italian offices: Strada Statale 25, n. 3 Via B Diotti,21 Via degli Oleandri, 8 10050 Bruzolo (TO) - Italia 20153 Milano - Italia 51100 Loc. Nespolo Tel.: +39 011 9635511 | Fax: +39 011 9635566 Tel.: +39 02 47999197 Chiazzano (PT) - Italia [email protected] Fax: +39 02 47997754 Tel.: +39 0573 935058 www.coord3.it | www.coord3-cmm.com Fax: +39 0573 539970 Full list of Agents & Distributors available at www.coord3.it DS05-MCT SL/Plus-EN-rev 00-04/09 page 4 All specifications listed in this brochure are subject to change without notice