Термоусадочное оборудование DIEBOLD - страница 29

Навигация

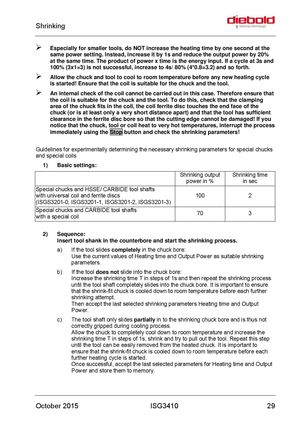

Shrinking Especially for smaller tools, do NOT increase the heating time by one second at the same power setting. Instead, increase it by 1s and reduce the output power by 20% at the same time. The product of power x time is the energy input. If a cycle at 3s and 100% (3x1=3) is not successful, increase to 4s/ 80% (4*0.8=3.2) and so forth. Allow the chuck and tool to cool to room temperature before any new heating cycle is started! Ensure that the coil is suitable for the chuck and the tool. An internal check of the coil cannot be carried out in this case. Therefore ensure that the coil is suitable for the chuck and the tool. To do this, check that the clamping area of the chuck fits in the coil, the coil ferrite disc touches the end face of the chuck (or is at least only a very short distance apart) and that the tool has sufficient clearance in the ferrite disc bore so that the cutting edge cannot be damaged! If you notice that the chuck, tool or coil heat to very hot temperatures, interrupt the process immediately using the Stop button and check the shrinking parameters! Guidelines for experimentally determining the necessary shrinking parameters for special chucks and special coils 1) Basic settings: Shrinking output Shrinking time power in % in sec Special chucks and HSSE/ CARBIDE tool shafts with universal coil and ferrite discs 100 2 (ISGS3201-0, ISGS3201-1, ISGS3201-2, ISGS3201-3) Special chucks and CARBIDE tool shaftswith a special coil 70 3 2) Sequence: Insert tool shank in the counterbore and start the shrinking process. a) If the tool slides completely in the chuck bore: Use the current values of Heating time and Output Power as suitable shrinking parameters. b) If the tool does not slide into the chuck bore: Increase the shrinking time T in steps of 1s and then repeat the shrinking process until the tool shaft completely slides into the chuck bore. It is important to ensure that the shrink-fit chuck is cooled down to room temperature before each further shrinking attempt. Then accept the last selected shrinking parameters Heating time and Output Power. c) The tool shaft only slides partially in to the shrinking chuck bore and is thus not correctly gripped during cooling process. Allow the chuck to completely cool down to room temperature and increase the shrinking time T in steps of 1s, shrink and try to pull out the tool. Repeat this step until the tool can be easily removed from the heated chuck. It is important to ensure that the shrink-fit chuck is cooled down to room temperature before each further heating cycle is started. Once successful, accept the last selected parameters for Heating time and Output Power and store them to memory. October 2015 ISG3410 29

Термоусадочные машины DIEBOLD серии ISG 3430 TLK

Термоусадочные машины DIEBOLD серии ISG 3430 TLK Термоусадочные машиныDIEBOLD серии ISG 3430 WK

Термоусадочные машиныDIEBOLD серии ISG 3430 WK Термоусадочные машины DIEBOLD серии ISG 2430 TWK

Термоусадочные машины DIEBOLD серии ISG 2430 TWK Термоусадочное оборудование DIEBOLD серии ISG 2430 WK

Термоусадочное оборудование DIEBOLD серии ISG 2430 WK Термоусадочное оборудование DIEBOLD серии ISG 2430 TLK

Термоусадочное оборудование DIEBOLD серии ISG 2430 TLK